机械特点 Characteristics ※立柱:采用门型双重壁加宽设计,氮气配重,高刚性、高稳定性。 ※主轴:高刚性190mm外径主轴,可追齿轮箱、齿轮头高扭矩带来最高的切削去除率。 ※X轴:大跨距高低轨道设计,重心与传动点完美配合,主轴与轨道间距离更接近,保证高速运行与重切削时的刚性。 ※底座:工作台,立柱全行程支撑结构,无悬空,精度稳定性高,加长型底座保证最大化工件旋转直径。 ※刀库:筒形凸轮分割机构,分割精度高,故障率低;双轴承分离式刀臂,同心度高,噪音小。 ※转台:采用日本双导程蜗轮蜗杆,油压齿式分度盘,使用寿命长,免维护,精度高,无需加装光栅尺。 ※全系统标配双螺杆加链条排屑机,排屑更方便,免人工。 总结:采用高稳定性T型机身结构,配合铸件内部最佳肋骨强化,保证最大化机床刚性与稳定性,标配双工作台自动交换功能,确保设备无间断运行,缩短工件加工周期,为您带来生产高效率、投入高回报率。 ※Vertical column: It adopts double-wall type of door widening design and nitrogen counterbalance weight. High rigidity and high stability. ※Spindle: High rigidity 190mm outer diameter spindle. The high torque traceable gearbox and gear head bring the highest cutting removal rate. ※X axis: High and low orbit design with large span. The center of gravity is perfectly matched with the transmission point and the spindle is more closer to the orbit. This ensures the machine rigidity even when it is working in high speed and heavy cutting conditions. ※Base: The working table and vertical column are total travel support structures without any suspending. High accuracy and stability. The elongated base ensures maximum rotating diameter of workpiece. ※Tool storage: Cylindrical cam segmented structure, high segmentation accuracy, low malfunction rate, double bearings split tool arm, high concentricity, low noise. ※Turntable: Using Japanese double lead worm and worm gear, hydraulic tooth index plate, long service life, maintenance-free, high precision, no need to install a grating ruler. ※System: The whole system is standardly equipped with twin screw and chain chip discharging machine and is more convenient with chip removal. Eliminating manual process. Summary: The base was used with high stability T fuselage construction with the best reinforcement of the internal ribs of the casting and that ensure the maximum machine rigidity and stability. The standard double working table automatic switching function provides the machine with uninterrupted operations and shortened workpiece processing cycle, and brings customers with high production efficiency and high return on investment.

15989519333 (Mr Xu)

Online consultation Message consultation| Main technical parameters | ||||

| Mechanical specifications | name | Specifications | Company | |

| trip | X-axis travel | 1100 | mm | |

| Travel Y-axis | 800 | mm | ||

| Z-axis travel | 1100 | mm | ||

| Distance from spindle nose to workbench center | 125-1225 | mm | ||

| Distance from spindle center to worktable | 50-850 | mm | ||

| workbench | Workbench size | 630×630 | mm | |

| Workbench indexing | 1 degree | |||

| maximum load | 800*2 | kg | ||

| Exchange station repetition accuracy | ±5” | |||

| T-shaped groove (number of grooves - size - spacing) | 24-M16-125 | mm | ||

| quantity | 2 | individual | ||

| principal axis | Spindle speed | 6000 | rpm | |

| Main spindle tool holder form | BT-50 | |||

| Spindle diameter | Ø190 | mm | ||

| Transmission mode | Belt type | |||

| Feed rate | Fast moving speed X/Y/Z | 20/ 20/ 20 | m/min | |

| feed rate | 1~8000 | mm/min | ||

| Machine accuracy | X/Y/Z-axis positioning accuracy | ±0.005/300 | mm | |

| X/Y/Z axis repetition accuracy | ±0.01 | mm | ||

| motor | Spindle motor | 15-18.5 (143-236NM) | KW | |

| X. Y and Z-axis drive motors | 36/36/36 | NM | ||

| Oil pump | DY-YBM-480 | W | ||

| Tool magazine | Tool magazine capacity | 40 | branch | |

| Automatic tool change type | Circular blade arm type | |||

| Knife handle specifications | BT-50 | |||

| Knife handle pull nail | 45 | degree | ||

| Maximum tool length | 400 | mm | ||

| Maximum tool diameter | Full of knives | Ø110 | mm | |

| Neighboring empty knife | Ø200 | mm | ||

| Maximum tool weight | 18 | kg | ||

| Tool change time | 2-5 | sec | ||

| Land occupation space | Mechanical height | 3500 | mm | |

| Floor space (length x width) | 5900*4300 | mm | ||

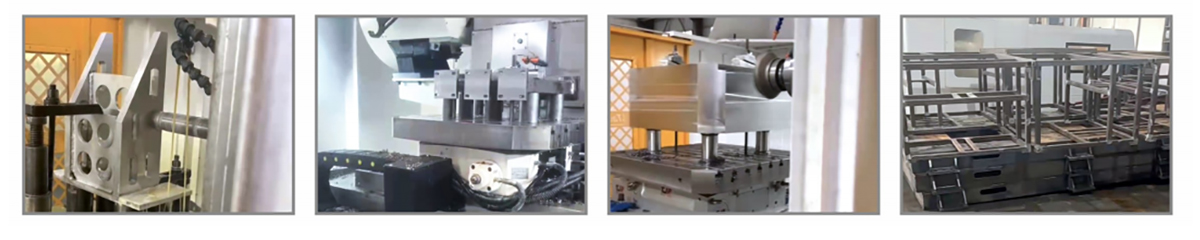

Processing applicationsProcessing application

Mold cutting, mold frame, cavity, motor housing

Efficient/ReliableHigh Efficient and Reliable

※ Quick movement X Y, Z: 30/30/30m/min (HPC650) three-axis standard cooling mechanism, simple structure, maintenance free

※ ATC tool change time: 2.5S (tool to tool) The servo tool library has a tool waiting position, which can be quickly changed through a cam type robotic arm. It can recognize heavy tools weighing over 20kg, making tool replacement stable and reliable.

High speed APC exchange time of 10 seconds, frame lifting structure, motor driven to achieve rotary exchange of workbench, fast and reliable.